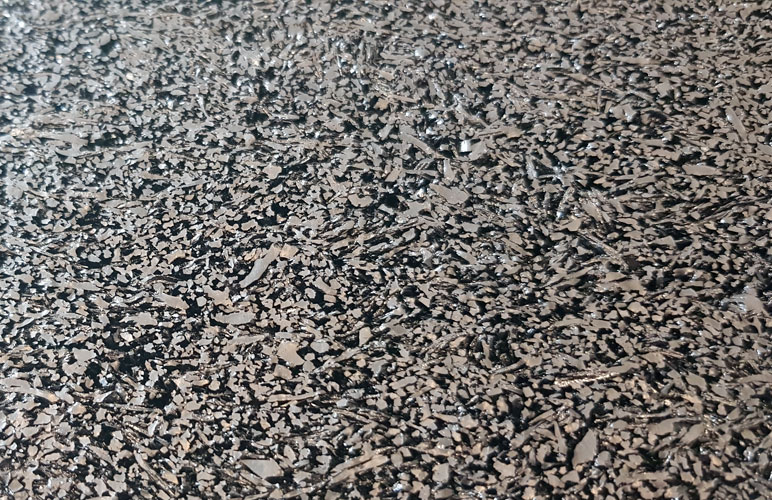

Composed of reclaimed rubber EPDM granulate and PUR binder H linoleum High Impact Acoustic Mat is an environmentally friendly alternative to traditional PVC carpet or rubber flooring and outclasses them in performance. It can be supplied in rolls or sheets in an extensive range of colours and finishes bespoke colours available on request.

CMS High Impact Acoustic Mat is a high performance material that has been tested by National Design Consultancy (Test report reference 80050 dated 3/3/1999) with the following test results

CMS High Impact acoustic mat is available in rolls and sheets to provide a seamless floor covering and as tiles. The material, which can be easily cut, is simple to install and ready for traffic just 24 hours after installation. Full and detailed installation guidelines are available on request.

The High Impact acoustic mat was used at the Balham branch of Waitrose to directly attenuate sound and withstand the impact of the delivery cages– metal cages used to carry stock generated high levels of noise when rolling across the uneven concrete floor, causing disturbance to residence.

CMS High Impact acoustic mat was installed in the Royal Shakespeare Theatres gantry to reduce unwanted noise generated by the movement of lighting and scenery during theatre performances.

CMS Bond 100 is a solvent free low VOC high performance water based acrylic dispersion with very good bond strength. It is suitable for plasticized vinyl floor coverings (including PVC tiles) together with high density foam backed carpets.

CMS Bond 100 is distributed in the UK by CMS Danskin Acoustics. The adhesive manufacturer will guarantee the performance and quality of products against manufacturing defects provided they are used in accordance with our relevant Technical Data Sheets at the time of installation and the appropriate sub floor preparation has been undertaken in accordance with the relevant British Standards.

Floor covering manufacturers are constantly introducing new backings and improving their current products. Certain backings may have unique characteristics which may influence the choice of adhesive used. Whilst every effort has been made to ensure the information is correct at the time of publication it is the responsibility of the user to ensure that the product is suitable for the particular installation.

If there is any doubt as to the use of our adhesives the installer should contact CMS Danskin Acoustics for advice or carry out their own tests to ensure compatibility.

Suitable sub-flooring substrates include concrete, flooring grade hardboard, plywood, chipboard, sand/cement screed, proprietary good quality self-smoothing underlayments. Asphalt and surface membranes should be treated with at least a 3mm coating of the latter before applying the adhesive.

Site conditions should comply with the latest British Standards editions: BS 8102 (Code of Practice for protection against moisture from the ground), BS 8203 (Code of Practice for installation of resilient floor coverings), BS 5325 (Code of Practice for installation of textile floor coverings), BS 8204 part 1 (Code of Practice for installation of self levelling screeding compounds), and supplementary specifications.

Surfaces must be level, firm and clean, free of loose material, mould, oil, grease, organic growth and surface moisture (under 75% RH).

Uneven, dusty or friable surfaces should be treated with the appropriate universal primer and screed.*

It is essential that suitable damp proof membranes be in place to prevent rising damp.*

Under floor heating should be turned off for at least 48 hours prior to and after application.

Particular attention must be paid to the floor covering manufacturer’s instructions. i.e. any pre storage conditions prior to fitting.

*Please contact CMS Danskin for further information.

CMS Bond 100 is a ready to use versatile product and should not be diluted or adulterated in any way.

Use a notched trowel of dimensions 1.5mm x 5mm or as CFA guidelines.

Heavy textured floor coverings may require a larger towel.

Apply adhesive evenly to the substrate and depending on the substrates lay the floor covering while still wet. It is best to allow the freshly applied adhesive to stand for 15-45 minutes depending on the ambient conditions, to build tack before embedding the floor covering.

Press firmly into place and rill using a 60/70Kg roller or glider depending on material used. Roll again approximately 1 hour after application.

Wait at least 24 hours before welding vinyl seams.

Clean tools with water if adhesive is still wet or use white spirits if it has dried.

| Product Specification |

| Colour | Off White |

| Consistency | Trowelable Mastic |

| Open Time | 15 minutes plus depending on site conditions: Temp, humid & surfaces to be treated |

| Specific Gravity | 1.2 |

| Shelf Life | 12 months if stored between 5-30°C in a dry area, in original unopened containers.

Protect from frost. |

| Product Technical Information |

| Curing | High humidity, a low temperature and poor ventilation will retard the drying speed |

| Coverage | 3m2/kg depending on the porosity of the substrate and thickness of the adhesive film. |

REGUPOL adhesive 46-101 represents the very latest development in Hybrid Polymer technology and has been formulated to give the highest levels of performance in terms of bond strength, versatility across many combinations of materials, improved acoustic performance in acoustic installations, resistance to stresses, fast curing speed and ease and cleanliness of use.

REGUPOL adhesive 43-105 is a solvent free acrylic emulsion-based adhesive, for bonding many sound insulation materials to common sub-floors and many floor finishes to the insulation. This easy to spread adhesive, with a long open time, provides early tack and minimum slip, quickly building to a strong permanent bond. It is non-staining and has excellent resistance to plasticiser migration.