FLSS - Seismic Control Restrained Spring Isolator

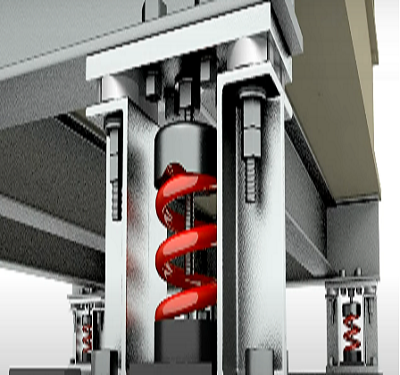

Kinetics Model FLSS Seismic Control Restrained Spring Vibration Isolators consist of free-standing, large diameter, laterally stable steel springs assembled into welded steel housing assemblies. The housings are fabricated to limit vertical movement of the isolated equipment if equipment loads are reduced or if the equipment is subjected to large external forces such as high winds or seismic events. The housings also provide a constant free and operating height to facilitate installation.

Spring elements are complete with internal noise isolation pads and leveling bolts as a part of the top load plate assembly. Holes are provided in all isolators for bolting to the structure and the supported equipment. To assure stability, the springs have a lateral spring stiffness greater than 1.2 times the rated vertical stiffness and are designed to provide a minimum overload capacity of 50%.

FLSS vibration isolators are available with deflections to 4″ (100 mm) and with load capacities to 23,200 lbs. (10523 kg) as standard products. Custom isolators with higher deflection and greater load capabilities are also available. Kinetics Model FLSS Spring Isolators are recommended for the isolation of vibration produced by equipment carrying a large fluid load which may be drained, such as boilers and chillers, and for the isolation of cooling towers, air-cooled condensers, etc., where motion due to wind loads must be minimized.

Application

Kinetics Model FLSS Seismic Control Restraint Spring Isolators are recommended as a noise and vibration isolator for mechanical equipment under the following conditions:

- When the mechanical equipment is located above or near noise and vibration sensitive areas.

- When the mechanical equipment is subjected to seismic events, high wind loads or other external forces.

- When the equipment to be isolated has significant changes of weight due to fluid drainage during maintenance operations such as boilers, chillers and cooling towers.

Operating static deflections are available up to 4″ (100 mm) to maintain a high degree of noise and vibration control while compensating for long span flexible floor structures.

Specification

Vibration isolators shall be seismically rated, restrained spring isolators for equipment which is subject to load variations and large external forces. Isolators shall consist of large diameter, laterally stable, steel springs assembled into welded steel housing assemblies designed to limit movement of the supported equipment in all directions.

Housing assembly shall be of fabricated steel members and shall consist of a top load plate complete with adjusting and leveling bolts, adjustable vertical restraints, isolation washers, and a bottom plate with internal non-skid noise isolation pads and holes for anchoring of housing to supporting structure. Housing shall be hotdip galvanized for corrosion resistance. Housing shall be designed to provide a constant free and operating height within 1/8″ (3 mm).

The isolator housing shall provide a minimum of 1 g restraint in all directions.

Spring elements shall be selected to provide static deflections as shown on the vibration isolation schedule or as indicated or required in the project documents. Springs shall be color coded or otherwise identified.

Spring elements shall have a lateral stiffness greater than 1.2 times the rated vertical stiffness and shall be designed to provide a minimum of 50% overload capacity. Non-welded spring elements shall be polyester powder coated, and shall have a 1000 hr rating when tested in accordance with ASTM B-117.

Vibration isolators shall be Model FLSS as manufactured by Kinetics Noise Control, Inc.