RSP - Elastomeric Isolators

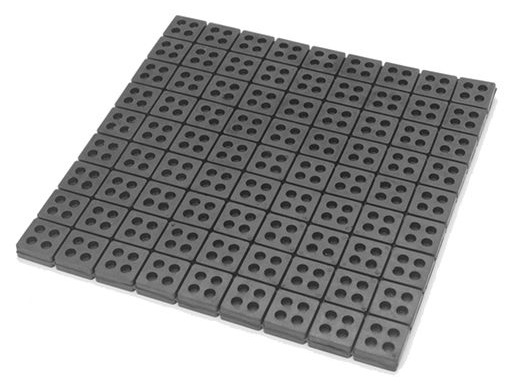

Kinetics RSP neoprene pads are produced from a high quality neoprene elastomer. Pads are 50 durometer and are designed for a maximum of 60 psi (4.2 kg. / sq. cm) loading. Pads are designed for a maximum deflection of approximately 20% of its unloaded thickness, 0.15″ (0.38 cm). Several layers of RSP pads can be stacked for additional deflection when steel separation shim stock is used. The elastomer is oil and water resistant, offers a long life expectancy consistent with neoprene compounds, and has been designed to operate within the safe stress limits of the material. RSP pads are available in 18″ x 18″ x 3/4″ (457 mm x 457 mm x 19 mm) thick sheets and are pre-scored into 2″ x 2″ (51 mm x 51 mm) squares.

Kinetics Model RSP elastomer in-shear isolation pads are suitable for the isolation of noise, shock, and high frequency vibration produced by mechanical, industrial, or process equipment located on grade, structural slab, or in other noncritical areas.

Applications for Model RSP pads should be limited to pad loadings not to exceed 60 lb. / sq. inch (4.2 kg. / sq. cm.) and are typically used with equipment or machinery having lowest operating speeds of 3600 rpm. Under shock or impact loading, the load capacity of the pads should be reduced by 50%.

Features

- Elastomer in-shear neoprene pads

- Oil, Water, and Corrosion resistant

- Available in 18″ x 18″ (457 mm x 457 mm x 19 mm) sheets, scored into 2″ x 2″ (51 mm x 51 mm) squares

- Load Capacities from 10 (0.7 kg. / sq. cm.) to 60 (4.2 kg. / sq. cm.) psi

- Static Deflections up to 0.15″ (4 mm)

Specification

Isolation pads shall be neoprene elastomer in-shear pads, used in conjunction with steel shims where required, having static deflections as tabulated.

All pads shall be elastomer in-shear and shall be molded using 2500 psi minimum tensile strength, oil resistant neoprene compounds with no color additives.

Pads shall be 50 durometer and designed to permit 60 psi (4.2 kg. / sq. cm.) loading at a maximum rated deflection of 0.15″ (4 mm). Pads shall be available in 18″ x 18″ x 3/4″ (457 mm x 457 mm x 19 mm) thick sheets, scored into 2″ x 2″ x 3/4″ (51 mm x 51 mm x 19 mm) thick pads. When two isolation pads are laminated, they shall be separated by, and bonded to, a galvanized steel shim plate.

Neoprene vibration isolators shall have minimum operating static deflections as shown on the Vibration Isolation Schedule, or as indicated on the project documents, but not exceeding published load capabilities.

Neoprene vibration isolators shall be model RSP as manufactured by Kinetics Noise Control, Inc.