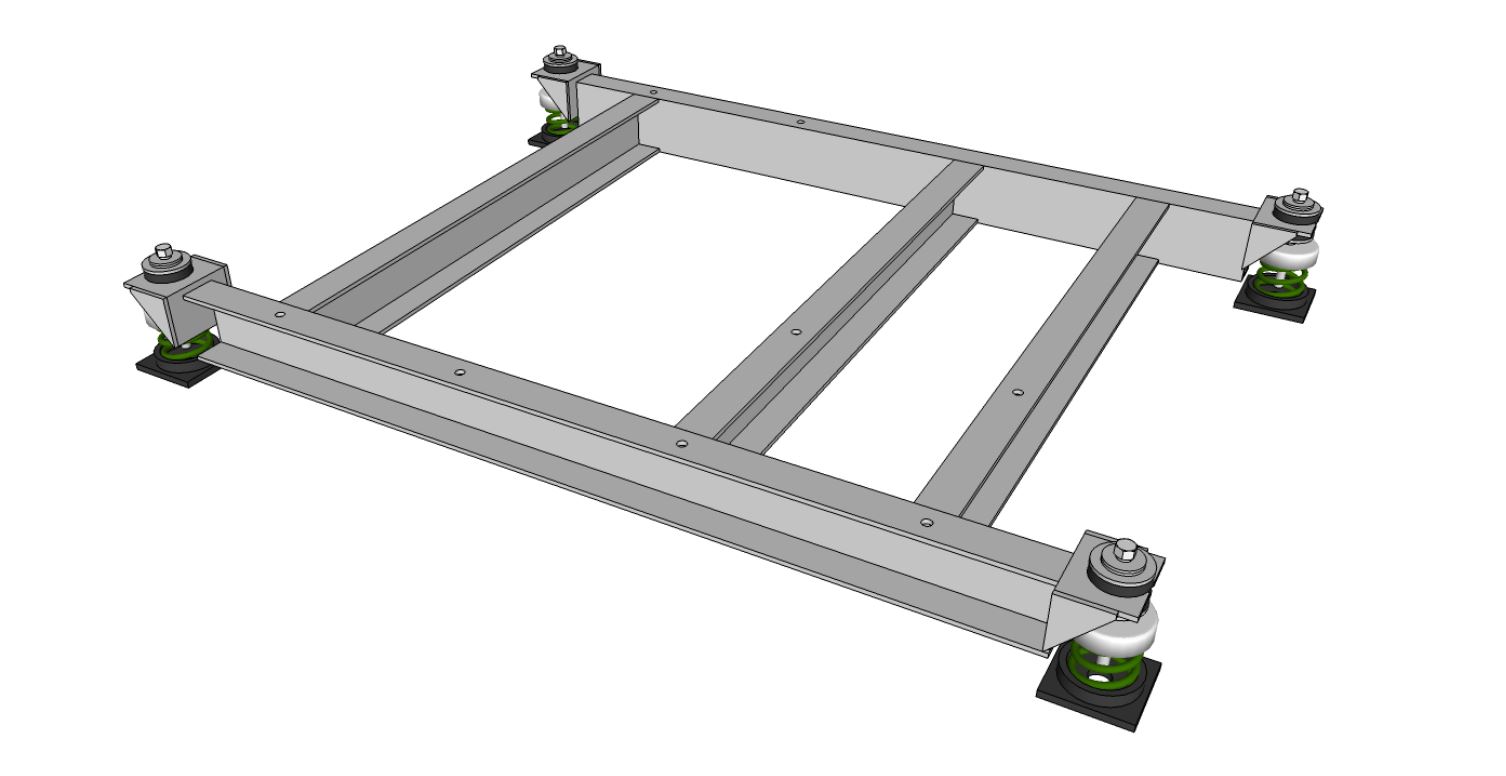

Kinetics Model SFB Structural Frame Bases are specifically designed and engineered to support mechanical equipment requiring a supplemental mounting frame.

Structural frame bases are used to support mechanical equipment and provide rigid platforms for attachment of vibration isolators, without allowing excessive differential movement between driving and driven members. The bases provide a means by which the equipment can be stabilized and motion reduced by lowering the equipment center of gravity.

Typical uses of Kinetics Model SFB structural frame bases, with Kinetics vibration isolators, include support and isolation of reciprocating chillers, close coupled pumps, vent sets, packaged air handling units, centrifugal fans, evaporative condensers, and similar types of equipment.