RIM is an easy to install, high-performance noise control system. The rolls of RIM use acoustic batting to prespace isolation pads which forms an airspace—an essential component for noise control.

RIM is an easy to install, high-performance noise control system. The rolls of RIM use acoustic batting to prespace isolation pads which forms an airspace—an essential component for noise control.

The KIP pad is at the core of RIM’s acoustic performance. Uniquely permanent and dynamically predictable, this isolation medium provides freedom of design due to its stable natural frequency across a wide range of variable loading situations. The pads are available in different sizes and densities with adjustable spacing in the roll of RIM. Shop drawings, which incorporate pad selection and spacing, are included with the system.

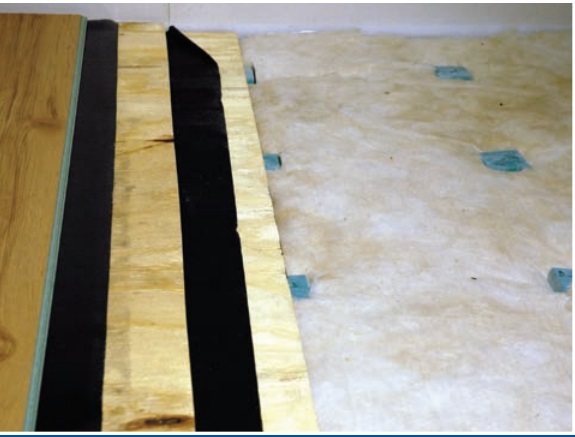

Compared to other high performing isolation systems, RIM installation is quick and simple. Each roll is designed so the pads line up with the adjacent unrolled material. After RIM has been laid out and installed, it is covered with plywood composite and finished flooring.

If better performance is required, consider adding more mass in the form of concrete. Find details here.

RIM System wood floated floors are ideally suited for dance studios, loft style condominiums, recording studios, and other applications where high performance noise control is required in conjunction with a lower profile, light weight assembly. A RIM System floated wood floor surpasses performance of continuous underlayments due to the airspace and lower natural frequency created by the KIP pads spaced at 12-, 16-, or 24-inches on center.

RIM System can be supplied to fit any load condition. In the cases of free weight drops like those seen in fitness centers, please consider that lightweight composite floors can prove insufficient standing up to shock loads. Damage to the lightweight floor and isolators can occur depending on the impact/shock loads. Contact Kinetics for guidance when designing these projects.

Typically, two layers of 3/4″ plywood are laid (seams staggered) over the isolation pads, and the finished floor is installed according to the manufacturer’s instructions. While two layers of 3/4″ plywood often proves suitable for most isolated wood floor composites, consider using three layers of plywood, glued and screwed together for added stiffness and mass, which aids in load distribution and noise control. Compare sound test AT001035 with AT001036 and discover how adding mass can boost STC results. The installation is completed by applying acoustical caulking to the top of the SRP board.

1) Place Perimeter Board (SRP)

2) Roll-out RIM

3) Build-up isolated subfloor

4) Apply finish floor per manufacturer instructions