Cast Stone Sills

Everything you need to know about our

External Cast Stone Window Sills

Benefits

CMS Danskin Acoustics’ External Cast Stone Window Sills are manufactured using high quality crushed rock fines and a blend of sands giving the appearance of natural stone.

Specification

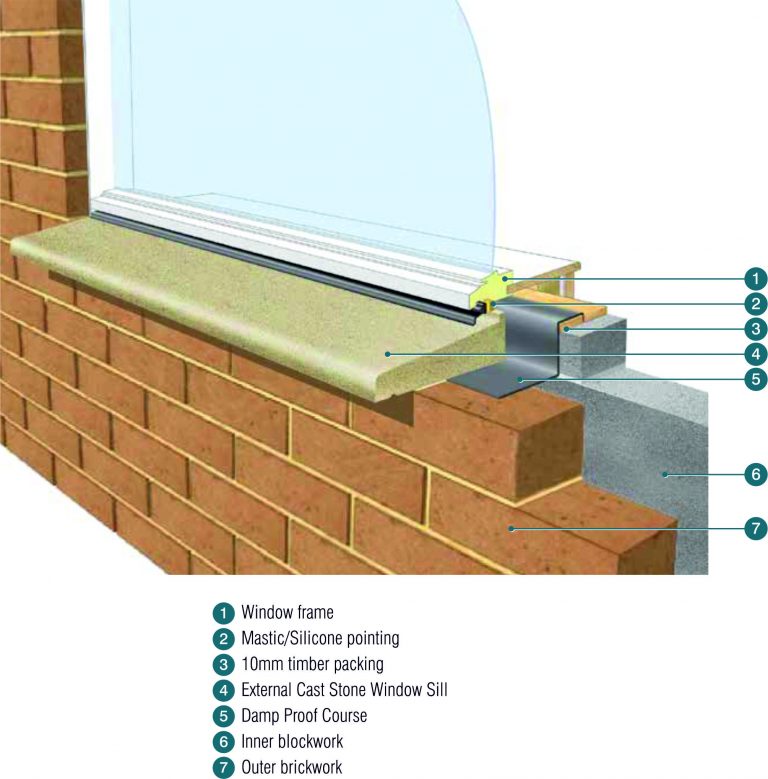

Installation

Cutting

External Cast Stone Window Sills should be cut with a diamond tipped masonry blade which should ideally be water fed. Once cut, all units should be washed down to remove any excess dust. Due regard should be given to protecting the operative in accordance with current Health & Safety considerations for dust suppression and elimination in the workplace.

Alternatively CMS Danskin Acoustics offer a cut to size service from the manufacturing factory in Wishaw, Scotland.

Four Colours

Available in Dark Grey, Light Grey and Brown. Buff can also be made order.

Dark Grey

Light Grey

Brown

Buff

Handling & Storage

CMS Danskin Acoustics cast stone external window sills are easy to handle, store and install. However,

special attention should be paid to the following information:

Storage

Site Handling

The safe handling of cast stone components is essential in order to ensure that they remain undamaged. Where handling information is not clear, contact the supplier for further recommendations.

Cutting

External Cast Stone Window Sills should be cut with a diamond tipped masonry blade which should ideally be water fed. Once cut, all units should be washed down to remove any excess dust. Due regard should be given to protecting the operative in accordance with current Health & Safety considerations for dust suppression and elimination in the workplace.

Alternatively CMS Danskin Acoustics offer a cut to size service from their facility in Wishaw, Scotland.

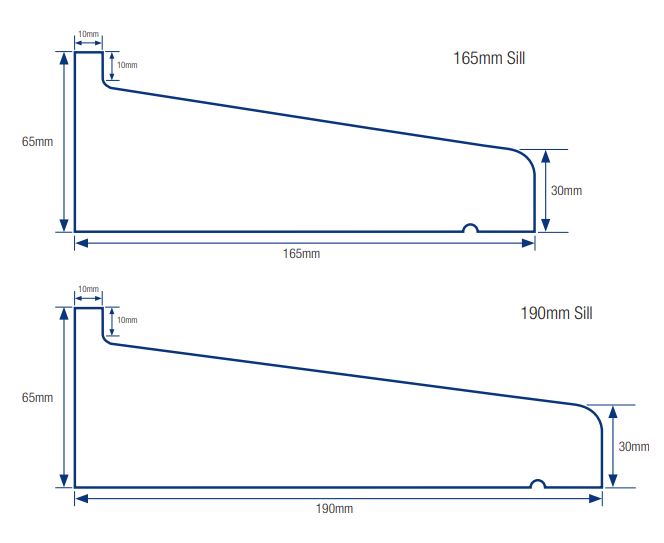

Sills Dimensions

Our cast stone sills are readily available in two profile widths 165mm and 190mm, and three standard lengths, 1.5m and 900mm.

Readily available in three profile widths 165mm, 190mm and 220mm, and three standard lengths, 1.5m, 1.2m & 900mm

Cutting Service

CMS Danskin Acoustics’ external cast stone window sills are easy to work with. For your convenience, CMS Danskin Acoustics offer a bespoke cutting service. Contact us for details.

Download Our Datasheet

Click on the icons below to download a PDF of our technical datasheet or installation guidelines.

Contact Info

Contact us using one of the methods below to discuss your building material needs.

CMS Danskin Scotland Office.

1 Netherton Road, Wishaw, North Lanarkshire, ML2 0EQ.

Phone Number

Email Us

Get In Touch

Fill in the form below and we will get back to you as soon as possible.