KSCR - Roof Curb and Vibration Isolation Rail

Affordable, easy-to-install, all-in-one roof curb and vibration isolation rail for under 12,000 lbs packaged rooftop units. Kinetics KSCR 2.0 features the redesigned KSR 2.0 vibration isolation rail.

The 2.0 Advantage

- Improved design with fewer components than the previous KSCR

- Extremely easy installation with factory assembled parts

- Pre-installed weather strip

- Pre-compressed springs means rail will be installed at the operational height

- Integrated seismic and wind restraints that do not require additional labor to install

- Isolation rail is engineered to meet the latest building code requirements

Standard Features

- Ships partially or fully assembled

- Vibration Isolation Rail | KSR 2.0

- 14″ high, 16 ga. galvanized steel lower support curb

- Horizontal and vertical seismic and wind restraints

- Extruded aluminum top and bottom members

- Universal fit, compatible with most curb-mounted equipment

- Continuous air- and water-tight seal strip

- Elastomeric corner seals

- Flexible duct connector supports

Options

- KSCR 2.1 – 1″ deflection and KSCR 2.2 – 2″ deflection

- Airborne noise control package

- Multiple roof pitch interface

- Certification of seismic and wind load engineering

Acoustical Treatments

Add an “in curb” acoustical treatment to Kinetics ESR vibration isolation curb to control breakout noise from equipment fans and compressors into the space below.

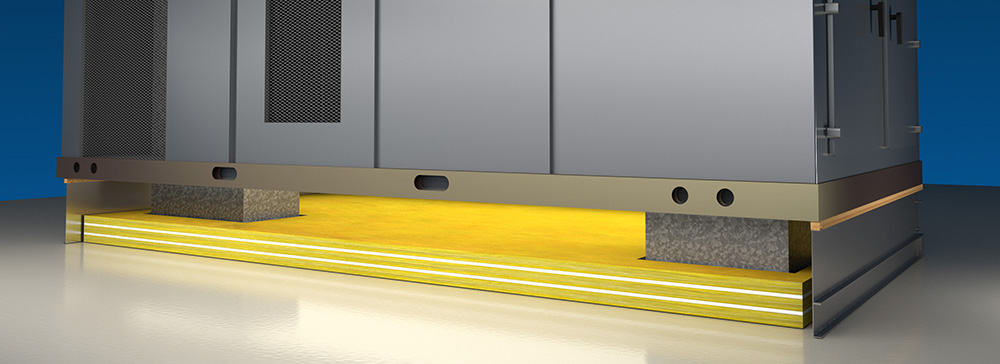

RT-7 Acoustical Treatment

STC 37 / 47 / 52 / 60

Exclusively from Kinetics Noise Control, specially designed to control breakout noise from rooftop equipment in curbs, RT-7 is a cost-effective solution and a contractor favorite due to its light weight and overall ease of installation.

NOISEBLOCK™ Acoustical Panels

STC 40 / 43 / 48 / 52

Kinetics versatile NOISEBLOCK acoustical panels are double-walled perforated metal panels. For rooftop equipment, Kinetics specifies 22-gauge perforated panels that are manufactured to fit and laid into the bottom of the curb delivering superior sound absorption (noise reduction) and transmission loss (noise blocking).

KRT Restraint Toggle

SEISMIC AND WIND RATED

Designed to secure attachment of unit to the roof curb. Kinetics KRT Restraint Toggle design allows for a secure attachment without requiring access to the inside of the curb, thus reducing number of restraints required and field labor.

Specifications

Vibration Restrained Curb-mounted Spring Rail: Model KSCR 3.0 – All rooftop air-handling units shall be supported by vibration isolation curbs as manufactured by Kinetics Noise Control. The vibration isolation curbs shall be complete assemblies designed to resiliently support the equipment at the specified elevation and shall constitute a fully enclosed air- and weather-tight system.

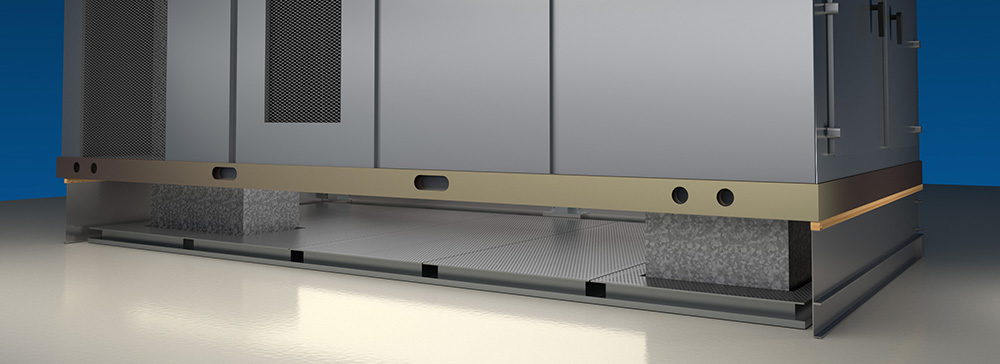

The isolation curb shall consist of an upper support rail with supply and return flexible connector supports on which the equipment and duct openings rest and a lower support curb which is attached to the roof structure, separated by free-standing, housed, adjustable, laterally stable steel springs with integral lateral seismic and/or wind load restraints.

The upper support rail shall provide continuous structural support for the rooftop equipment and shall be designed to provide isolation against casing-radiated vibration in the rooftop equipment housing and structure-borne vibration from rotating and mechanical equipment in the rooftop package.

The lower support curb shall be a formed channel fabricated of heavy gauge galvanized steel with a continuous 1-1/2″ x 1-1/2″ (38 mm x 38 mm) nominal wood nailer. The lower support curb shall have a minimum elevation of 14″ (356 mm). Spring components shall be 1″ (25 mm) 2″ (51 mm) deflection. Springs shall have a lateral stiffness greater than 1.0 times the rated vertical stiffness and shall be designed for a typical 50% overload to solid. All springs shall have a polyester powder coated finish and be color coded to indicate load capacity.

Upper support rail and lower support curb are connected by adjustable spring isolators and covered by a continuous air- and water-tight seal drape. Rail assemblies shall incorporate means for attachment to the building and the supported equipment and shall incorporate additional stiffening members if necessary to assure stability.

Supply and return flexible connector support hardware shall be supplied. The supports will be clearly marked and dimensioned on the submittal and installation drawings. The support hardware shall be cut-to-length, galvanized steel channels supported and connected with stamped and punched galvanized steel duct support hangers. The support hangers shall allow the duct support elevation to be equal to or lower than the equipment rail elevation. Supply and return air duct shall be flexibly attached by the contractor to prevent transmission of vibration to the building structure.

The isolation curb assemblies shall be shipped to the job site with the upper support rail, lower support curb, springs, and seal strip. The contractor shall assemble the four corners and attach the curb to the roof structure then adjust springs per factory specifications.

Vibration isolators shall be selected by the manufacturer for each specific application to comply with deflection requirements as shown on the Vibration Isolation Schedule or as indicated on the project documents. Roof curb shall be Model KSCR 3.0 as manufactured by Kinetics Noise Control.