Reflex Bearer

Everything you need to know about our Reflex Bearers

Advantages

Application

Specification

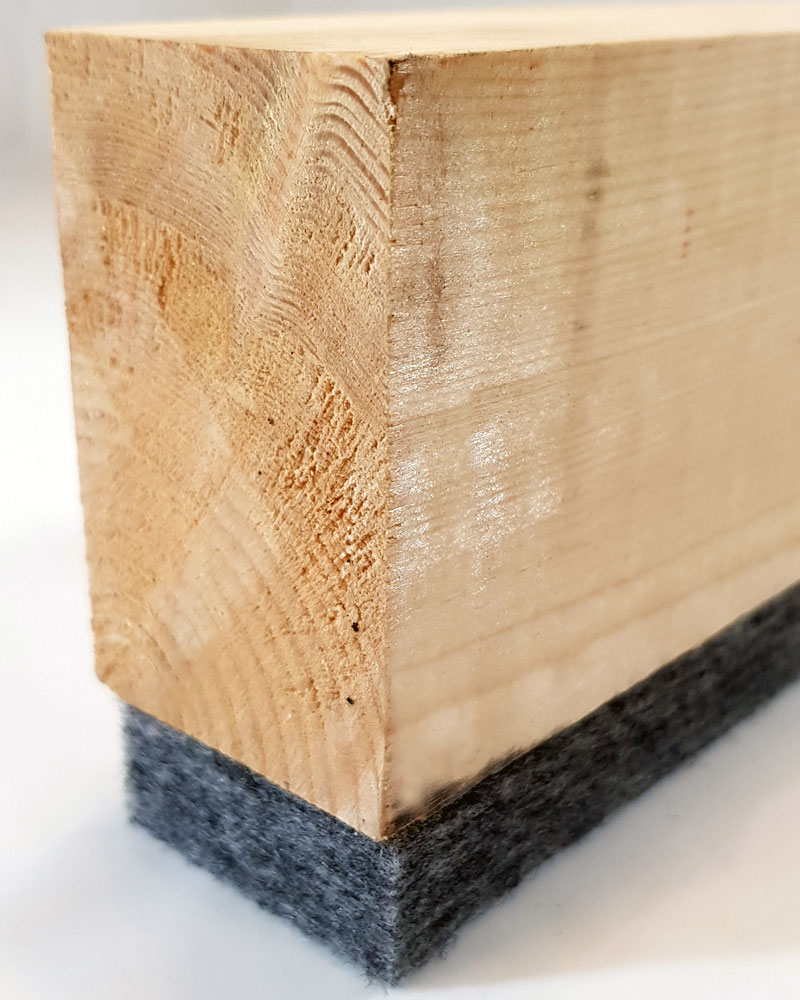

Reflex Bearer Acoustic Battens comprise softwood battens 45mm ( Nom.) wide by 2400mm long with a specially developed resilient fibre strip 17mm thick adhered to the underside. They can be preservative treated if required. On average it is expected that the resilient layer will compress by around 4mm under normal loading.

Standard Heights ( unloaded ) : 53mm , 75mm and 87mm ( Nom.)

Other sizes are available to order. Timber is FSC certified as standard.

For FFT1 requirements use a 75mm Reflex Bearer Acoustic Battens.

For FFT3 requirements use a 53mm Reflex Bearer Acoustic Battens or higher.

Performance

Laboratory values for Reflex Bearer Acoustic Battens are shown below.

Please request CMS Danskin Performance Data sheets for test information on the Reflex Bearer Acoustic Battens with different structural floor and ceiling combinations.

Accessories

High Load Bearers

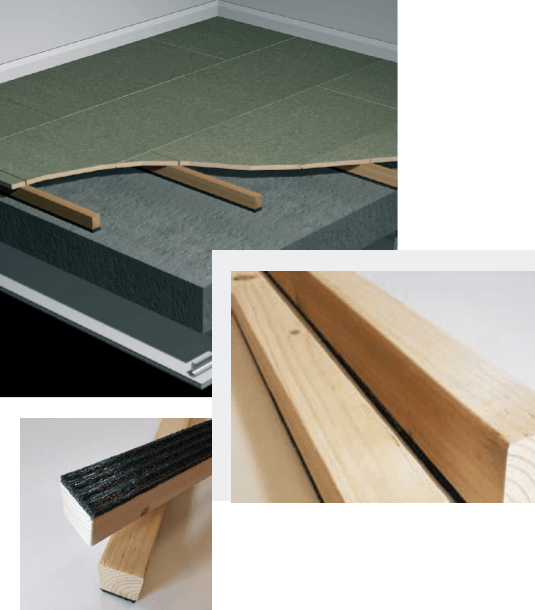

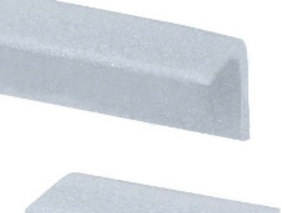

It is an essential feature of effective floating floors that they deflect vertically in order to absorb impact energy and therefore reduce sound transmission. However effective deflection under areas of high load such as kitchen and bathroom furniture is not desirable. While this can sometimes be lessened by reducing batten centres or using double rows of Reflex Bearer Acoustic Battens, limited numbers of high density foam battens can sometimes be used in these local areas. On concrete subfloors High Load Bearers are also recommended for use at room perimeters. As High Load Bearers have a lesser acoustic performance than Reflex Bearer Acoustic Battens a warning message regarding excessive use is printed on the top surface. High Load Bearers are manufactured to a similar height as compressed Reflex Bearer Acoustic Battens ( ie, Reflex height less 4mm ) and provide superior support.

Danskin Flanking Strip

This is placed at the perimeter of each floor . The 6mm thick preformed “L” shaped acoustic foam is supplied in strips 1.8m long and packed in bags of 100 lineal metres.The innovative “L” shape makes the flanking strip easy to fit and one size fits all floors. It is lightly trapped between the bottom of the skirting and the top of the flooring board with the excess neatly trimmed off.

Danskin Acoustic Quilt

( as required )

Where required to achieve a particular acoustic performance CMS Danskin can supply acoustic quilt.

Thickness : 25mm

Density : 19 kg/m2

Roll size : 22.5 metres long x 1.2 metres wide.

Chipboard Flooring

18mm or 22mm thick P5 T&G chipboard flooring with optional protective or decorative layers.

Sheet size : 2400 x 600

Danskin D3 Adhesive

Danskin D3 adhesive is a high quality resin based wood adhesive which provides a high strength impact resistant bond. It conforms to the international standard EN 204 (D3) and BS 4071 for creep resistance.It is supplied in 1 litre bottles.

Acoustic

Bearers

CMS Danskin Acoustics’ range of resilient acoustic bearers is designed to reduce impact and airborne sound in a wide range of separating floors.

PARK BEARERS

REFLEX BEARERS

Benefits of Acoustic Bearers

Environment

Acoustic bearers incorporate sustainable timber. Wherever possible the timber used is homegrown to minimise transportation. The Global Warming Potential (GWP) of the resilient layers on the Park and Reflex Bearers is zero.

Acoustic Bearer Product Selector

| Product | Uneven Subfloors | Level Subfloors (*1) | Compatible Subfloors (*2) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cast Insitu | Precast Planks | Steel/Concrete Composite | Beam & Block | Solid Timber Joists | Timber I Joists | Metal Web Joists | Steel Joists | |||

| Park Bearers | ||||||||||

| Reflex Bearers | ||||||||||

*2 – When used with suitable ceiling construction. This table is indicative only. If uncertain, please check with CMS Danskin Acoustics.

Bearer Centres

Bearer centres must not exceed 400mm for 18mm chipboard or 600mm for 22mm chipboard based on a maximum UDL of 1.5kN/m2 and concentrated load of 2 kN. Bearer centres should be reduced to 300mm where heavy loads are anticipated. e.g kitchens and bathrooms.

Where anticipated loads exceed these figures please contact CMS Danskin Acoustics.

Park Bearer

Park Bearers are designed for use on level concrete and steel/concrete composite separating floors as part of a suitable floor and ceiling construction.

Timber floating floors incorporating Park Bearers can provide effective sound insulation on concrete subfloors and eliminate the delays caused by the drying out of screeds.

The cavity created by acoustic bearers can accommodate service runs and underfloor heating systems under the floor.

Park Bearers consist of softwood timber battens 2400mm long by 45mm wide with a specially developed 9mm thick resilient foam strip adhered to the underside.

| Length | Width (*1) | Height (*2) | Height Benchmark (*3) |

|---|---|---|---|

| 2400mm | 45mm | 54mm | FFT3 |

| 2400mm | 45mm | 79mm | FFT1 |

Notes :

*1 – Park Bearers comply with the WPIF Code of Practice for Particle Board and OSB Floating Floors (3/2018) which specifies a minimum finished batten width of 45mm.

*2 – It is anticipated that the resilient layer will compress by around 2mm under a UDL of 25kg/m2

*3 – This refers to the batten height category. Please also refer to the FFT performance table on the next page for appropriate use.

Park Bearer FFT Performance Qualification

| Design Approach | Performance Requirements | Tested Performance |

|---|---|---|

| England & Wales Robust Detail Constructions (*1) | ||

| E-FC-1 - Precast Concrete (min. FFT3 batten) E-FC-2 - In-situ Concrete (min. FFT3 batten) E-FC-7 - Beam and Block (min. FFT3 batten) E-FC-1 - Steel/ In-situ Concrete (min. FFT3 batten) |

FFT3 Batten to be at least 45mm high (compressed) Minimum rd∆ Lw 17dB |

54mm Park Bearer rd∆ Lw 24dB |

| Scottish Robust Detail Construction | ||

| V-FS-1 Steel/In-situ concrete (min. FFT3 batten) | FFT3 Batten to be at least 45mm high (compressed) Minimum rd∆ Lw 17dB |

54mm Park Bearer rd∆ Lw 24dB |

| Scottish Example Constructions | ||

| Floor type 1B Insitu concrete slab with FFT Floor type 2B Precast concrete slab with FFT |

FFT3 Batten to be at least 45mm high (compressed) Minimum ∆ Lw 22dB Minimum ∆ Rw 5dB |

54mm Park Bearer ∆ Lw 26dB, ∆ Rw 8dB |

Park Bearer Accessories

L-Shaped Flanking Strip for perimeter isolation.

Thickness: 6mm

Length: 1.8m

Acoustic quilt (as required).

Laid between bearers for enhanced sound reduction.

Flooring Boards

- Smartspan (for use with underfloor heating )

- P5 flooring grade chipboard

- Engineered Spruce flooring grade plywood

Reflex Bearers

CMS Danskin Acoustics have produced an innovative flooring bearer with an exceptional level of acoustic performance which contributes significantly to the reduction of impact and airborne sound through timber and steel joisted party floors.

The Reflex Bearer incorporates a unique resilient fibre layer which provides a high degree of impact sound reduction.

Reflex Bearers are ideal on level timber or lightweight steel joist subfloors as part of a suitable base floor and ceiling construction.

Reflex Bearers consist of softwood timber battens 2400mm long by 45mm wide with a unique fibre resilient layer adhered to the underside.

| Length | Width (*1) | Height (*2) | Height Benchmark (*3) |

|---|---|---|---|

| 2400mm | 45mm | 53mm | FFT3 |

| 2400mm | 45mm | 75mm | FFT1 |

| 2400mm | 45mm | 87mm | FFT80 |

Notes :

**1 – Reflex Bearers comply with the WPIF Code of Practice for Particle Board and OSB Floating Floors (3/2018) which specifies a minimum finished batten width of 45mm.

*2 – It is anticipated that the resilient layer will compress by around 4mm under a UDL of 25kg/m2.

*3 – This refers to the batten height category. Please also refer to the FFT performance table on the next page for appropriate use.

Reflex Bearers FFT Performance Qualification

| Design Approach | Performance Requirements | Tested Performance |

|---|---|---|

| England & Wales Robust Detail Construction (*1) | ||

| E-FT-1 - Timber I Joists (FFT1 batten) E-FT-2 - Timber Solid Joists (FFT1 batten) E-FT-3 - Metal Web Joists (FFT1 batten) E-FS-2 - Metal Joists (FFT1 batten) |

FFT3 Batten to be at least 70mm high (compressed) Minimum rd∆ Lw 15dB Minimum rdDelta Rw + Ctr 13dB |

75mm high Reflex Bearer rd∆ Lw 22dB rd∆ Rw + Ctr 16dB |

| E-FT-7 - Timber I Joists (FFT80 batten) E-FT-8 - Timber Solid Joists (FFT80 batten) |

FFT80 Batten to be at least 80mm high (compressed) Minimum rd∆ Lw 16dB Minimum rd∆ Rw 17dB Minimum rd∆ Lw + Ctr 13dB |

87mm high Reflex Bearer rd∆ Lw 23dB rd∆ Rw 18dB rd∆ Rw + Ctr 17dB |

| Scottish Robust Detail Construction | ||

| V-FT-1 - Timber I Joists (FFT80 batten) V-FT-2 - Timber Solid Joists (FFT80 batten) |

FFT80 Batten to be at least 80mm high (compressed) Minimum rd∆ Lw 16dB Minimum rd∆ Rw 17dB Minimum rd∆ Lw + Ctr 13dB |

87mm high Reflex Bearer rd∆ Lw 23dB rd∆ Rw 18dB rd∆ Rw + Ctr 17dB |

| Scottish Example Constructions | ||

| Floor type 3A Timber Frame Floor with Solid Joists Floor type 3B Timber Frame Floor with Engineered I Joists |

FFT1 Batten to be at least 70mm high (compressed) Minimum ∆ Lw 16dB Minimum ∆ Rw 17dB Minimum ∆ Rw + Ctr 13dB |

75mm high Reflex Bearer ∆ Lw 22dB ∆ Rw 17dB ∆ Rw + Ctr 16dB |

Reflex Bearer Accessories

L-Shaped Flanking Strip for perimeter isolation.

Thickness: 6mm

Length: 1.8m

Acoustic quilt (as required). Laid between bearers for enhanced sound reduction.

High Load Bearers. An option in limited areas for additional support.

Flooring Boards

- Smartspan (for use with underfloor heating )

- P5 flooring grade chipboard

- Engineered Spruce flooring grade plywood

Our Commitment

The aim of CMS Danskin Acoustics is to correctly interpret the requirements of our customer and, where available, to offer appropriate evidence that our floating floors are suitable for use within their separating floor design. Where our customer requires specific acoustic design advice we will be pleased to assist in directing them to a suitably qualified acoustic consultant.

Floating floor treatments are only one part of a separating floor structure and the correct design, installation and workmanship of the total construction is essential to ensure satisfactory performance. Any evidence provided about the compatibility of a CMS Danskin Acoustics acoustic flooring product is dependent on the customer providing complete and accurate construction information.

The type of evidence which is necessary to justify the inclusion of our products is dependent on the approach taken by the customer to satisfy the regulations.

For each approach the evidence we can generally offer is as follows:

installation

To ensure correct installation of floors the manufacturer`s detailed fixing instructions must be followed carefully. Copies of these instructions are available from CMS Danskin Acoustics.

Contact Info

Contact us using one of the methods below to discuss your building material needs.

CMS Danskin Scotland Office.

1 Netherton Road, Wishaw, North Lanarkshire, ML2 0EQ.

Phone Number

Email Us

Get In Touch

Fill in the form below and we will get back to you as soon as possible.