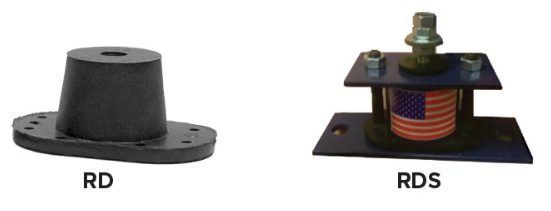

RD/RDS – Elastomeric Vibration Isolators

Features

- Molded neoprene isolator

- Encapsulated tapped steel load plate

- Encapsulated drilled steel anchor/baseplate

- Load capacities 55 lbs to 4000 lbs (25 kg to 1814 kg)

- Seismic and wind restraint option (RDS)

- Standard Powder Coated Finish (RDS); Painted Mounts Available (RDS)

Application

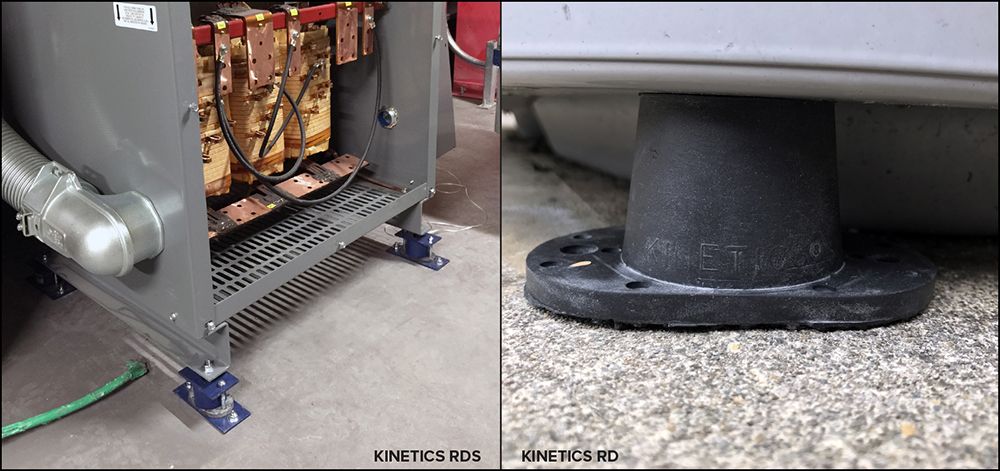

Kinetics RD/RDS neoprene mounts are recommended for the isolation of vibration produced by small pumps, vent sets, low pressure packaged air-handling units, and other mechanical equipment. Typical applications are limited to isolation of high frequency vibration generated mechanical equipment having the lowest operating speeds of 1750 RPM when located on a grade-supported slab or pier, and include close-coupled pumps with motors of 5 H.P. or less.

Kinetics RD/RDS neoprene isolation mounts can be used for isolation of mechanical equipment specified to be supported by neoprene rubber or elastomer isolators and with tabulated minimum static deflection up to 0.50″ (13 mm).

Description

Specifications

Vibration isolators shall be neoprene, molded from oil-resistant compounds, with cast-in-top steel load transfer plate for bolting to supported equipment, and a bolt-down plate with holes provided for anchoring to supporting structure. Bottom surfaces shall have non-skid ribs.

Neoprene vibration isolators shall have minimum operating static deflections as shown on the Vibration Isolation Schedule or as indicated on the project documents but not exceeding published load capabilities.

Neoprene vibration isolators shall be Kinetics RD and RDS, as manufactured by Kinetics Noise Control, Inc.