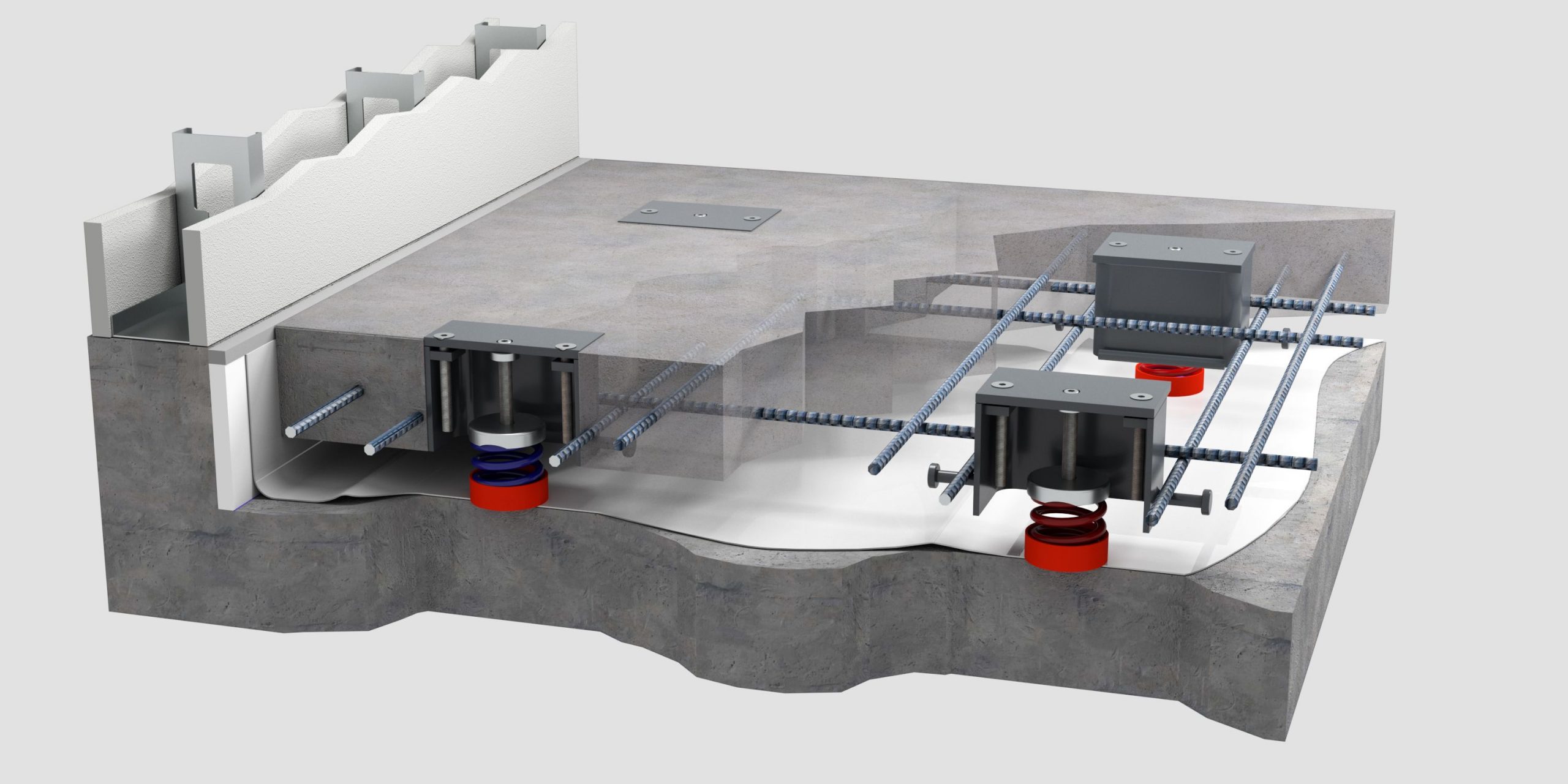

Need to isolate a concrete slab exposed to significant vibration and impact activities such as experienced in a fitness space, basketball court, generator room, or bowling center? Consider LSM spring isolator assemblies, a viable product solution for addressing vibration and impact, especially when noises generated by these activities are deemed more problematic than airborne noise transmission.

LSM – Spring Lift Slab Floor Mount

Fabricated, made-to-spec housings permit flexible isolation system design for a range of slab thicknesses, air cavities, and applied loads. Your acoustical design team can assist you with your specific requirements.

Required deflection and corresponding natural frequency for the floor isolators can be determined using one inch (1″) or two inch (2”) rated coil springs. Ask us about options for the airspace between the isolated (lifted) slab and the structural slab.

Factory-prepared shop drawings detail spacing, spring load/deflections, and structural floor flatness requirements. Our Project Coordinators and Professional Engineers are ready to assist you with your specific design questions.

Rubber cap assembly protects spring coils against resonant or “ringing” frequencies.

Based on your floor system requirements, in-slab or perimeter seismic restraint elements as well as Coulomb Dampers and other damping components are easily designed.

LSM can ship in ready-to-install sub-assemblies. For instance, canister assemblies and related accessories can ship ahead of the spring assemblies based on pour schedule requirements. Spring assemblies can follow once the slab is cured to strength and ready to be raised helping eliminate “missing parts” just when you are ready to lift.