ISO Acoustic Enclosure Panels

Download Product Data SheetProduct

The CMS Danskin Acoustics Enclosure Panel System consists of prefabricated building panels, jointing accessories and fittings designed primarily for the construction of noise-protected structures in industrial environments.

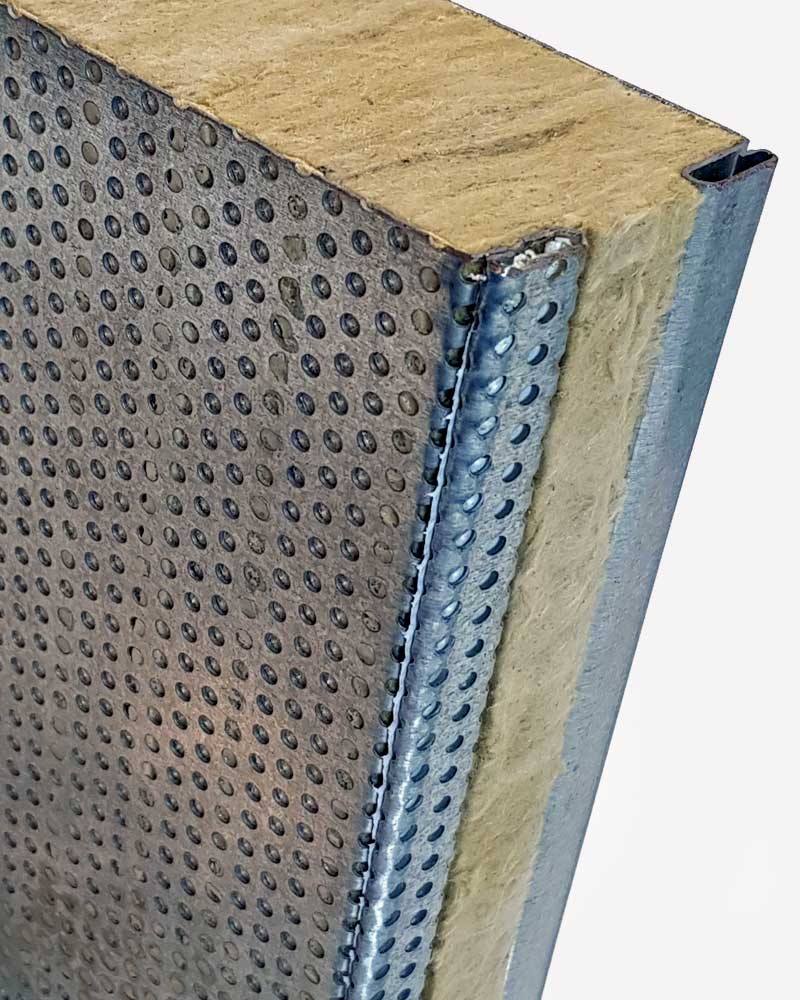

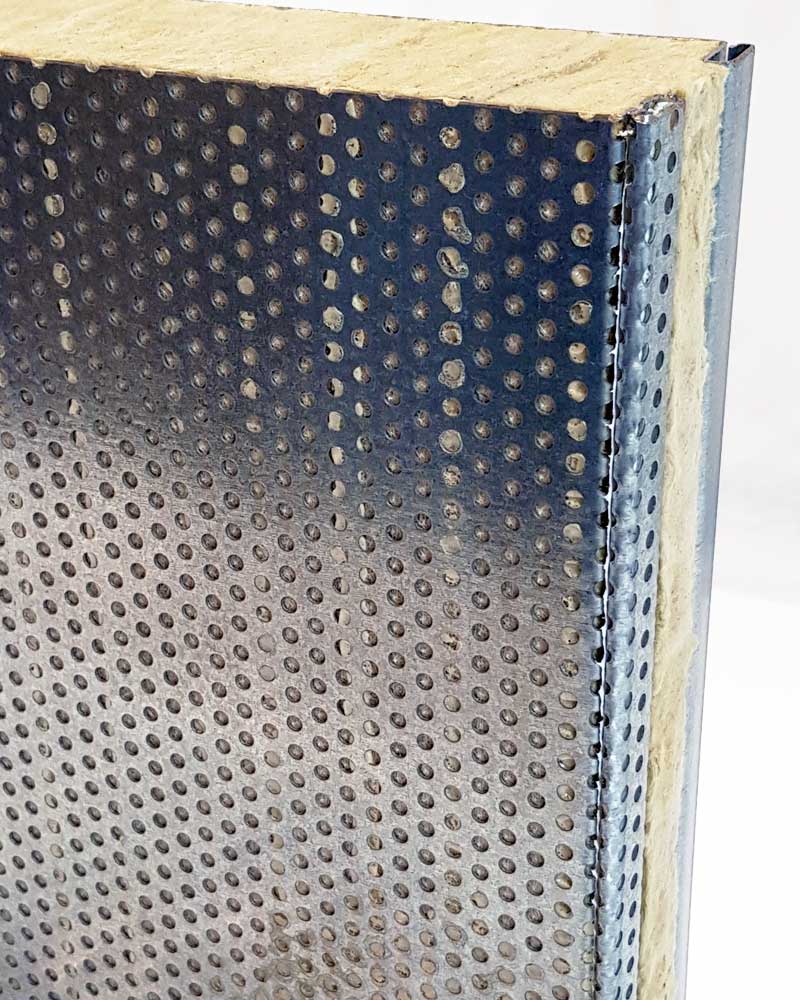

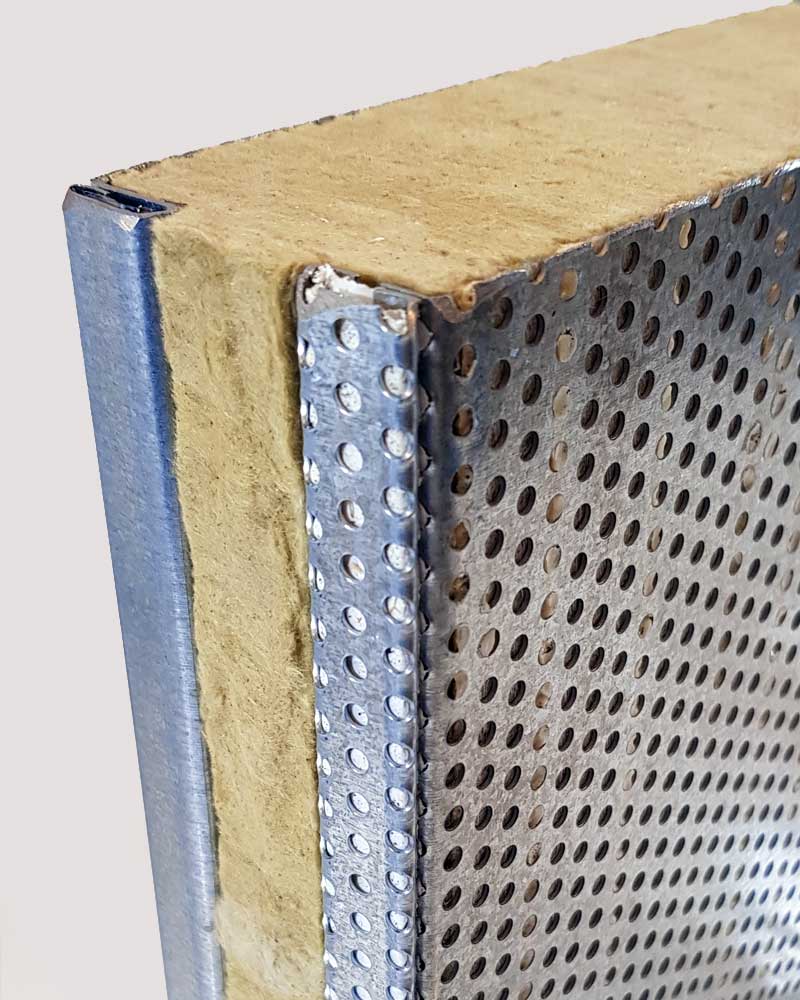

They are used typically for industrial offices, acoustic enclosures for machinery, acoustic screens and sound havens. The panel elements consist of a core of transverse mineral wool bonded to surface layers of solid or perforated 0.7 mm hot-dip galvanised steel sheet (stainless steel or aluminium are available to special order). These panels are rigid and self-supporting* and can be fitted with doors and windows as required. Panels can be finished in polyester powder paint or PVC foil in a range of colours.

All components may be supplied in standard sizes or as a customised kit of parts to your specification. A full range of corner, T-piece and jointing profiles are available to enable any floor pan to be accommodated. Panels may be mounted both vertically and horizontally.

Construction is simple, requiring only a jigsaw to cut panels. Fastening of adjacent panels is achieved by a simple but secure system which runs the full length of each panel; this clip system allows panels to be easily dismantled for maintenance access and for changing layouts.

The use of jointing compounds on mating services produces an airtight seal, giving optimum acoustic performance and making this method of construction suitable for clean-rooms and fan rooms.

*A supporting structure is needed for large spans and for external applications where high wind loads are present.

FEATURES and BENEFITS

- High sound reduction.

- Extremely robust self supporting construction.

- Lightweight and easy to handle.

- Panels can be easily demounted and relocated.

- Flush finish surfaces no protruding components.

- Custom delivery schedules.

- Product solution with all assembly profiles and fittings

- Short assembly profiles and fittings.

- Short assembly time, typically one fifth of traditional structures

- Easy to work, no special tools required.

- Can be used inside and out

- Can also be supplied and installed through our nominated installer

- Turn-Key approach through CMS Danskin Acoustics installation partners