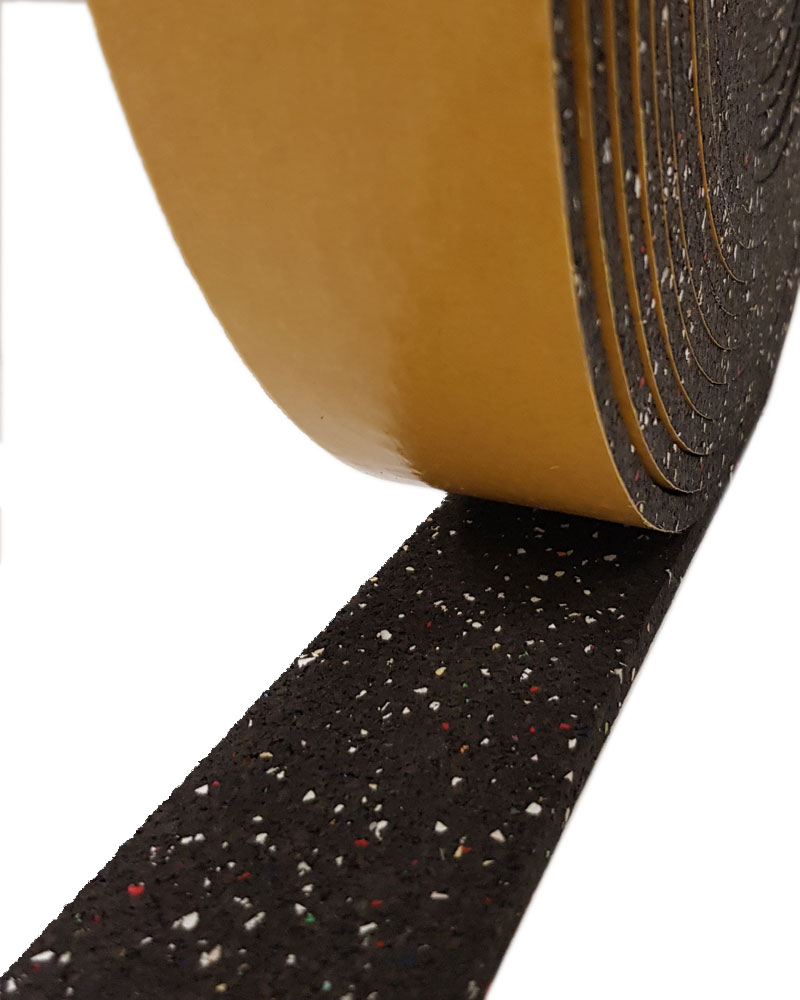

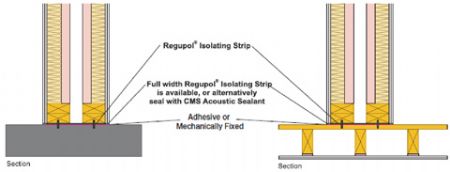

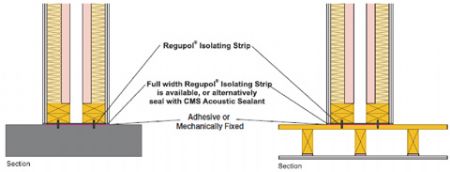

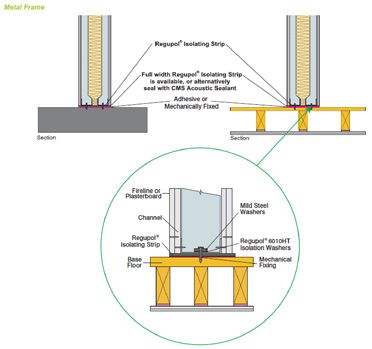

We have Regupol® Acoustic Isolating Strips (REGUPOL sonus 3912 Isolation Strips) both timber/metal stud frames. Just click on the appropriate tab for more detailed information.

Regupol® Acoustic Isolating Strips (REGUPOL sonus 3912 Isolation Strips) are designed to isolate noise and vibrations at source.

Regupol® Acoustic Isolating Strips (REGUPOL sonus 3912 Isolation Strips) are a very simple and effective way to reduce structure borne noise. There are a number of different Regupol® materials that can be installed as isolating strips each one tailored to withstand a specific weight per linear metre therefore we have a Regupol® solution for all particular requirements.