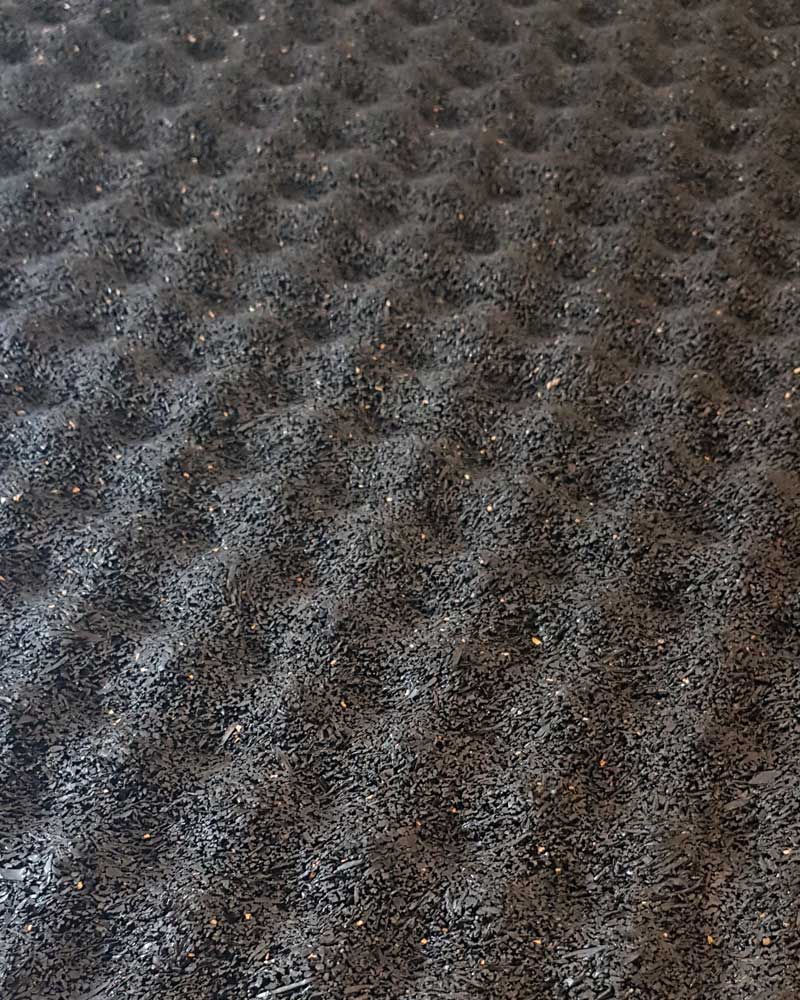

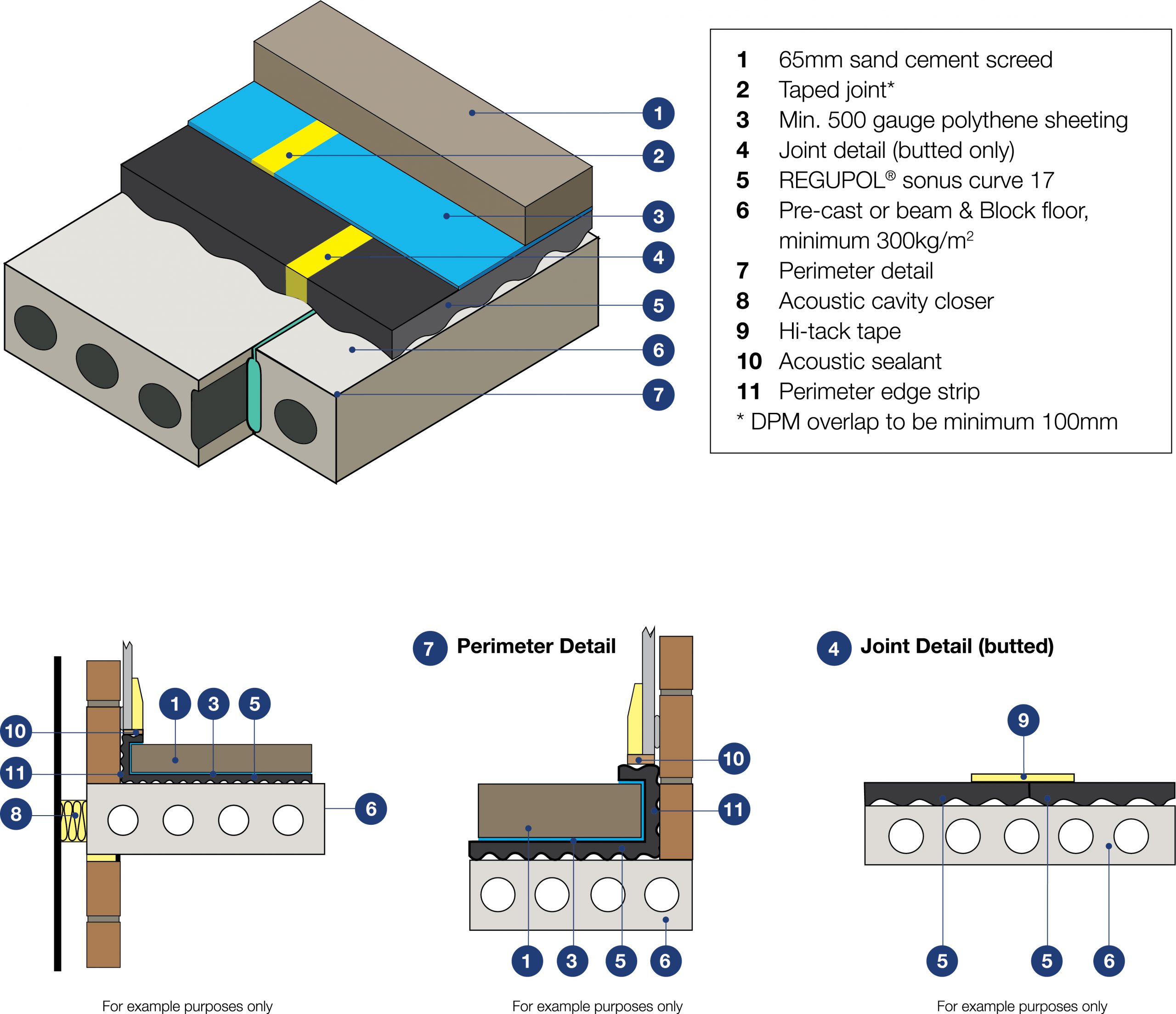

Regupol 6010BA (REGUPOL sonus curve 17) Acoustic Screed Underlay is a high-load bearing recycled tyre crumb product designed for use where high loads are apparent yet acoustic performance is critical with performance requirements exceeding that of the standards quoted in approved Document E 2010.

Regupol 6010BA (REGUPOL sonus curve 17) Acoustic Screed Underlay is a high load bearing screed isolation solution. It delivers effective isolation and impact sound insulation even under heavy loads

Regupol 6010BA (REGUPOL sonus curve 17) is often the preferred choice for

premium developments and those where superior

acoustic performance is critical.