18mm T&G chipboard laid over Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment adhered to 18mm T&G chipboard, directly fixed to timber joists, 8” x 2”, with 75mm mineral wood between joists and two layers of 12.5mm thick plasterboard fixed to resilient bar.

| Acoustic Performance of Regupol® 3912 (REGUPOL sonus 3912) Acoustic Underlayment - Example 1 |

| Airbourne sound Insulation Rw (C;Ctr) | 54dB (measured in accordance with BS EN ISO 140-3:1995 |

| Impact Sound Insulation (Lntw) | 43dB (measured in accordance with BS EN ISO 140-6:1998 |

8mm T&G chipboard laid over 19mm plasterboard plank, over Regupol® 3912 (REGUPOL sonus 3912) Acoustic Underlayment adhered to 18mm T&G chipboard, directly fixed to timber joists, 8” x 2” and two layers of 12.5mm thick plasterboard fixed to the joists.

Acoustic Performance of Regupol® 3912 (REGUPOL sonus 3912) Acoustic Underlayment - Example 2

|

| Airbourne sound Insulation Rw (C;Ctr) | 49dB (measured in accordance with BS EN ISO 140-3:1995 |

| Impact Sound Insulation (Lntw) | 55dB (measured in accordance with BS EN ISO 140-6:1998 |

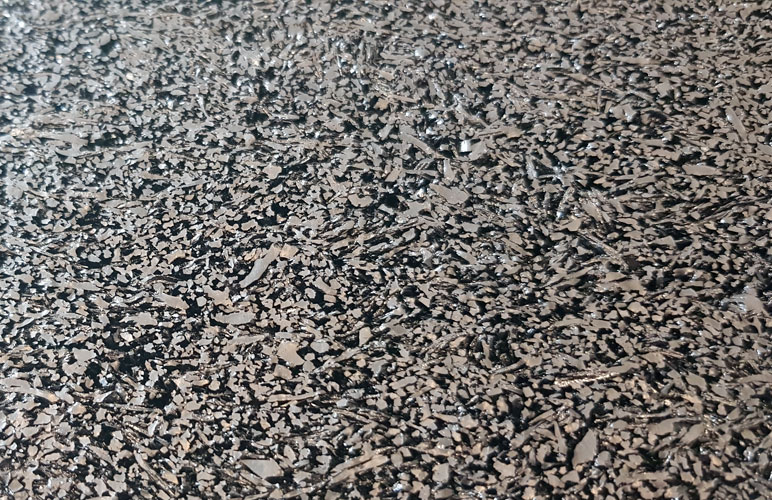

Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment is a very versatile product within the refurbishment market and can also be used with batten floor systems, an example of which is detailed across.

18mm T&G chipboard fixed to timber battens laid on Regupol 3912 (REGUPOL sonus 3912) adhered to 18mm T&G chipboard.

Subfloor preparation is essential for the correct installation of Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment. Subfloors must be sound, smooth, dry and free from any contaminants which could affect adhesion.

Please ensure each roll of Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment is completely unrolled, turned over and left in the area to which it is to be applied for a minimum of 6 hours or ideally overnight prior to cutting and installing.

Bond Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment to the base floor. The Regupol 3912 Acoustic Underlayment should be bonded to the subfloor using one of our recommended adhesives – please contact CMS Danskin for a list.

Please ensure the adhesive guidelines are followed at all times.

Lay the Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment into the adhesive and press from the centre outwards to exclude air and ensure overall contact with the adhesive.

Roll the Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment with a 68kg flooring roller, from end to end and side to side to ensure overall contact.

Please leave a minimum gap of 3mm around the entire perimeter to allow for expansion and contraction. Do not butt the Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment against the skirting boards and/or carpet grippers.

Use a craft knife and straight edge for cutting to size and please ensure that all edges are butt jointed.

After 30 minutes, when the floor has been completely covered, roll once again to ensure contact is maintained.

Please do not apply loads or move furniture on the Regupol 3912 (REGUPOL sonus 3912) Acoustic Underlayment until the adhesive has fully set. Please refer to the adhesive manufacturer’s installation guidelines for curing times.

REGUPOL adhesive 46-101 represents the very latest development in Hybrid Polymer technology and has been formulated to give the highest levels of performance in terms of bond strength, versatility across many combinations of materials, improved acoustic performance in acoustic installations, resistance to stresses, fast curing speed and ease and cleanliness of use.

REGUPOL adhesive 43-105 is a solvent free acrylic emulsion-based adhesive, for bonding many sound insulation materials to common sub-floors and many floor finishes to the insulation. This easy to spread adhesive, with a long open time, provides early tack and minimum slip, quickly building to a strong permanent bond. It is non-staining and has excellent resistance to plasticiser migration.