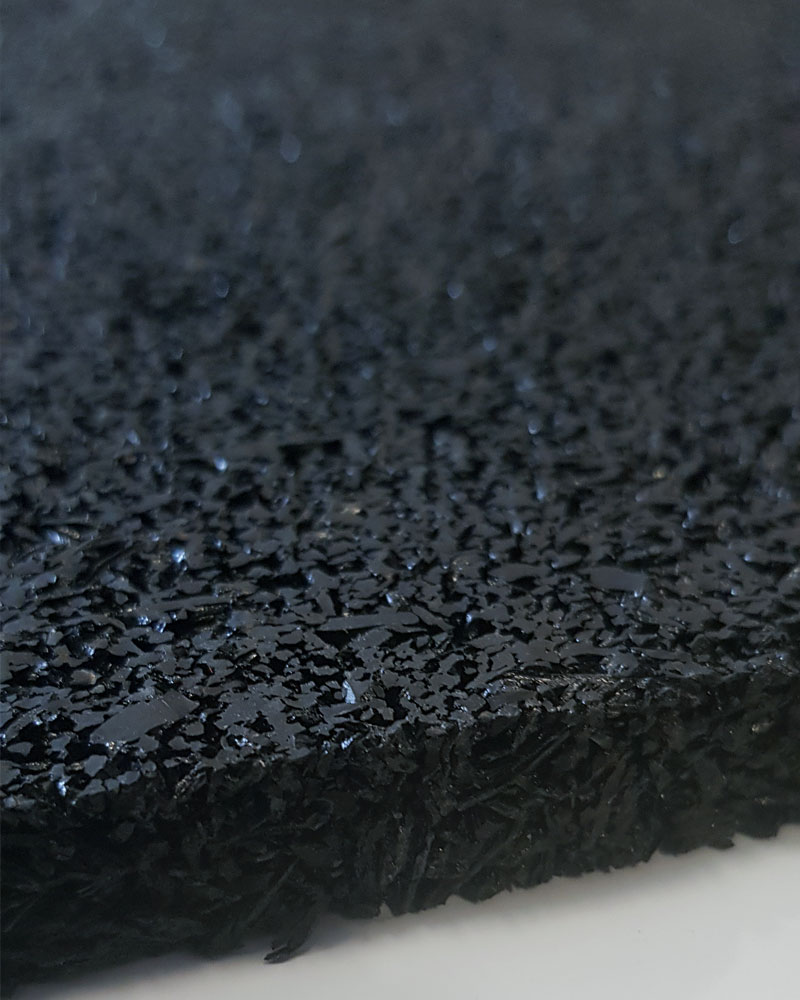

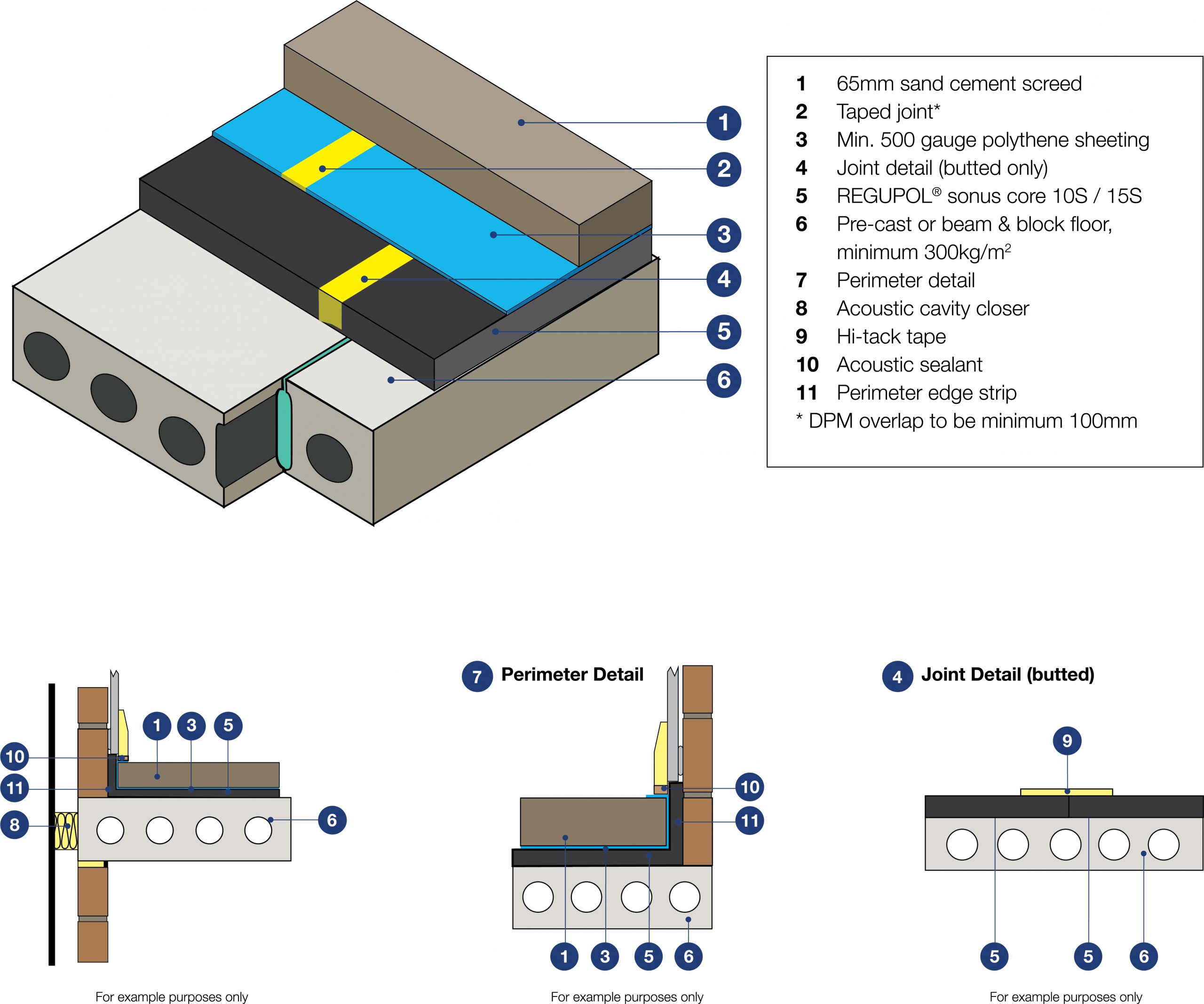

Regupol 6010 SH (REGUPOL sonus core 10-S and REGUPOL sonus core 15-S) Acoustic Screed Isolation Material is a recycled tyre crumb product designed for use where very high loads are apparent yet acoustic performance is critical with performance requirements exceeding that of the standards quoted in Approved Document E 2003.

Regupol 6010 SH (REGUPOL sonus core 10-S and REGUPOL sonus core 15-S) Acoustic Screed Isolation Material enhances the impact and airbourne acoustic properties of timber floors where loads exceed that of standard constructions. For use in new build and refurbishment applications.