Unwanted vibrations and shock impact occur in nearly all technical equipment and machinery − but elastic bedding with the well-known materials Regupol® and Regufoam® reliably prevent the distribution of these vibration forces.

BSW has produced, sized and supplied material for the vibration isolation of machine foundations for over 20 years.

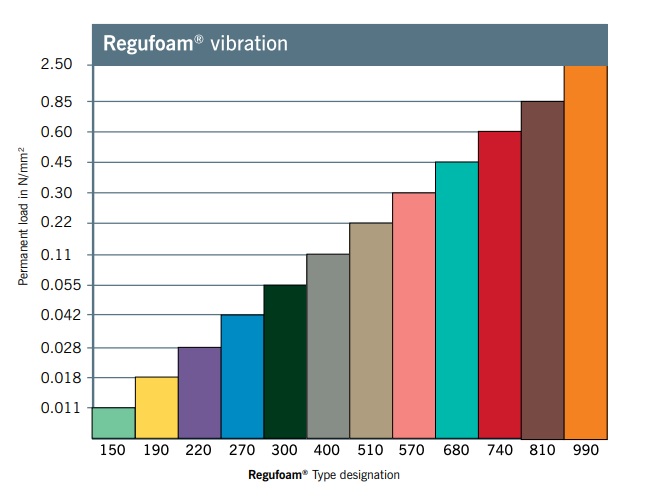

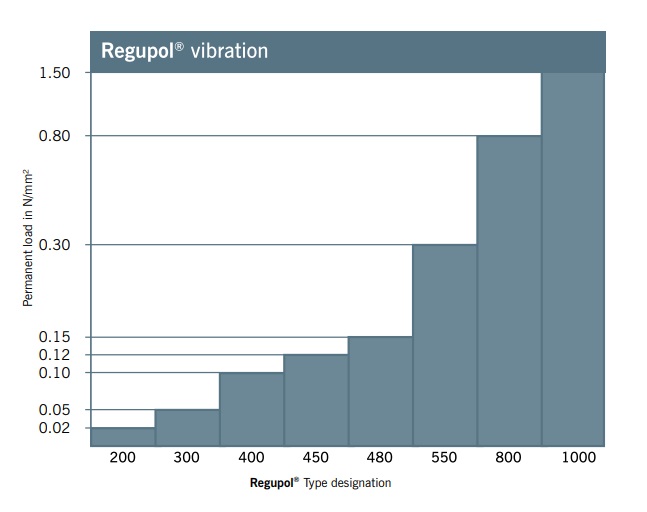

The material Regupol® is composed of rubber fibres, rubber granulates (SBR, NBR) and polyurethanes, and Regufoam® is a mixed-cell polyurethane foam.

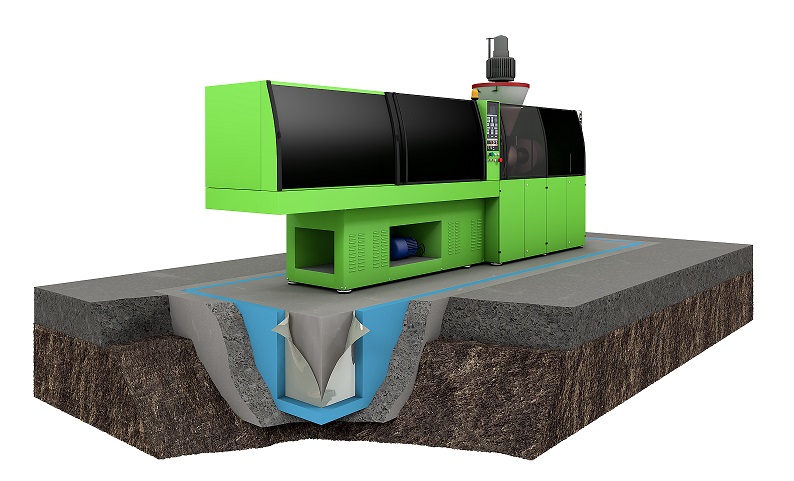

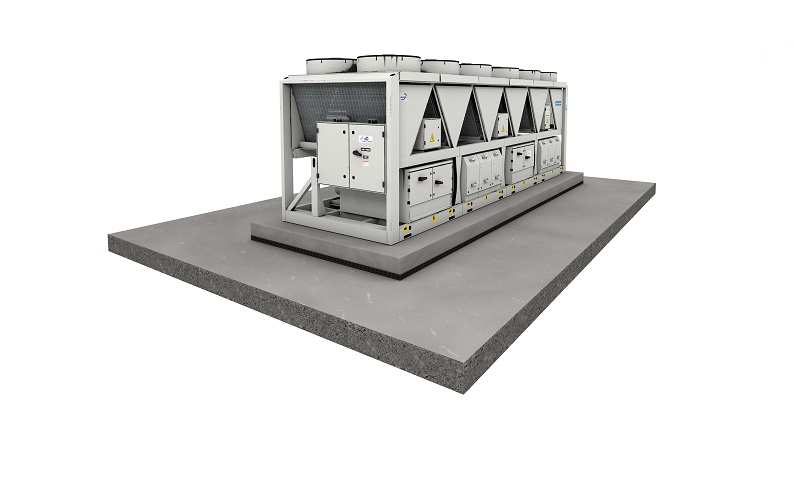

Probably the most important measure for reducing the vibration impact of machinery in a building structure and its surroundings is the elastic decoupling of the machine foundations.

We distinguish between “active” and “passive” vibration isolation. In active isolation the spread of vibrations is reduced, and in passive isolation sensitive equipment is protected against ambient vibrations.

Generally speaking, active isolation of the source is the preferred solution, as this measure can protect larger impact areas and thus several objects.

Regupol® and Regufoam® are subdivided into 8 or 12 load ranges each. As a consequence, they can cover a broad spectrum of vibration-technology-related applications. Thanks to the rigidities of the selected materials, the settlement behaviour is the same for nearly all types.

This provides the expert consultants for vibration technology issues with two product groups that are helpful to them in developing the most economical and technically best solution possible.