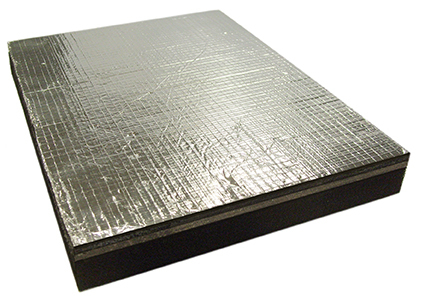

CMS Danskin Acoustics SUPERLAG® Pipe Lag is a product consisting of a four part laminate including two acoustic isolation layers or spacers of polyurethane acoustic foam, separated by a heavy mass layer or acoustic grade lead or polymeric barrier with a facing of Class ‘0’ reinforced foil. SUPERLAG® Pipe Lag is available in a range of formats by varying the weight and type of the mass barrier and selecting from three thicknesses of acoustic spacer layers to suit the performance required.

SUPERLAG® Pipe Lag

Technical information for SUPERLAG® Pipe Lag

Acoustic Heavy Mass Sheet Barrier

Surface weight: 5 kg/m2or 10 kg/m2

Composite

Operating Temperature: -30 to 80oC

Application

CMS Danskin Acoustics SUPERLAG® Pipe Lag is a highly efficient acoustic treatment designed for rainwater pipes, pneumatic & hydraulic pipes, and waste water pipes for industrial, commercial & construction applications. Steam pipes can also be treated with SUPERLAG® Pipe Lag providing a suitable thermal insulation is applied as the first layer in direct contact with the pipe face. Being of a foam laminate construction, it is ideal where fibre erosion is not acceptable and where a significant reduction in break-out noise is specified.

Features and Benefits

- Easy and quick to apply.

- Excellent acoustic performance.

- Applied as a single treatment.

- Low thermal conductivity.