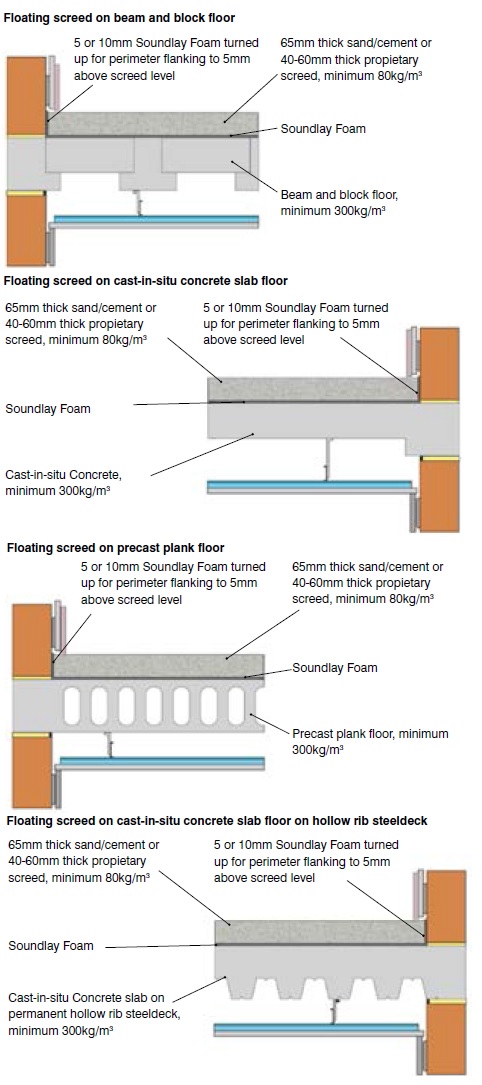

Soundlay Foam Under Screed Isolation Material is a cross-linked closed cell polyolefin foam which is ideal as a low cost resilient under-screed layer designed to reduce the transmission of impact sound through cast in–situ beam and block and precast plank flooring.

The foam contains EVA rubber cells to give improved acoustic performance and increased resistance to compression and creeping.